Kiln furniture

Kiln furniture refers to refractory parts that are used as furnace equipment. The main purpose of kiln furniture is to create more space for holding ceramic products during firing in the kiln. Ceramist use kiln furniture to organize the empty space of the kiln so they can use it efficiently to accommodate ceramic parts of different shapes and sizes.

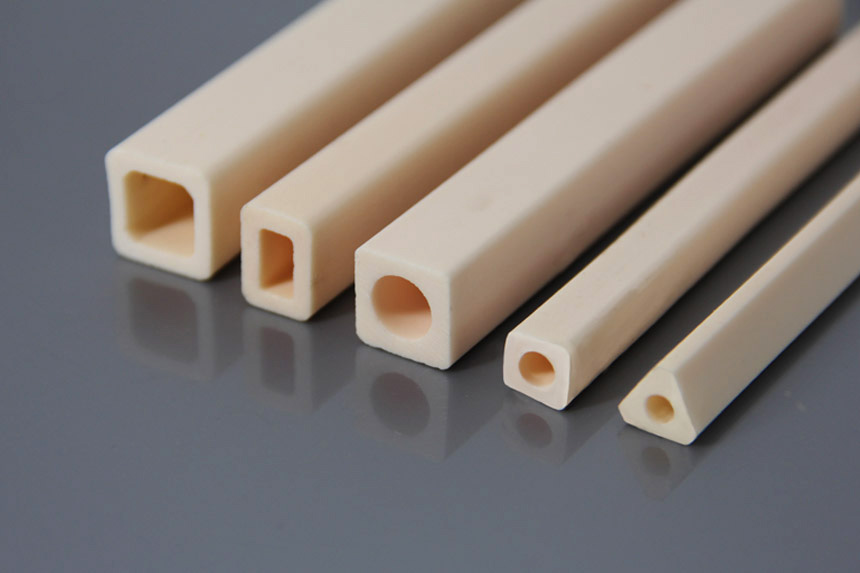

Kiln furniture has a great variety of shapes and includes simple to complex shapes like shelves, stilts or pernettes, saggars and etc. they also are produced in different sizes. Depending on the material which is used for producing kiln furniture, they can be used in different temperatures and thermal conditions. It is very important to choose suitable kiln furniture because choosing the wrong furniture can lead to ruining the whole operation.

ALTUS electrofused products made with care and precision are the best choice for manufacturing ceramic bodies and shells.

ALTUS