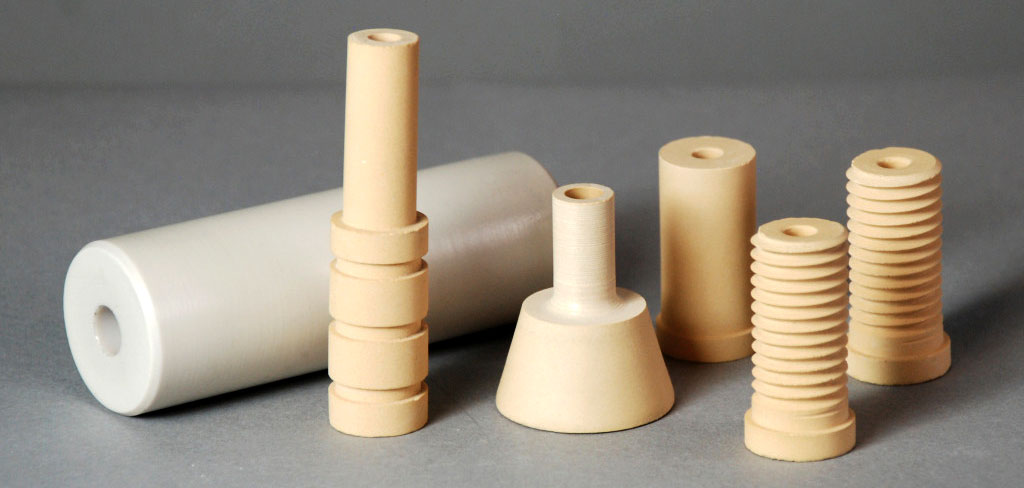

Ceramic Bodies and Shells

One of the common applications for any ceramic raw material is the production of ceramic bodies and shells. Usually when certain characteristics like refractoriness or inertness are needed ceramics come into play. Based on their application these may need different properties like maximum operating temperature, corrosion and oxidation resistance, mechanical and thermomechanical strength, thermal shock resistance, wear resistance and etc. There are many varieties of ceramic bodies and shells which differ in composition, shape, geometry and etc.

Most of the produced ceramic bodies and shells operate at high temperatures. Operating at high temperatures doesn’t just need materials with high melting points it means the performance of material at high temperatures should be similar or at least with little difference compared to its performance at normal temperatures. For example, the produced bodies should have suitable mechanical strength, chemical stability, and wear resistance at the temperature in which it performs. Kiln furniture, spark plug bodies, and shells used for investment casting are some examples of high temperatures of ceramic bodies and shells.

ALTUS electrofused products made with care and precision are the best choice for manufacturing ceramic bodies and shells.

ALTUS